Professional Lifting Equipment

for All Type of Contractors

We offer a wide range of quality products: rack and pinion hoists, cutting & bending machines and light machinery.

Being the first manufacturer of collective protection systems to investigate damage with dummies. But our value does not lie only in the product itself, but also in our pre-sales and after-sales service, by offering a technical assistance support if needed, in order to the start-up, use and operation of our lifts.

- Glass suckers lifter

- Construction material lifter

- Pallet lifter

- Cherry picker

- Maintenance platforms lifter

- & All equipment lifters ...

TRAKTELO

Professional, affordable and we always

leave the seat down

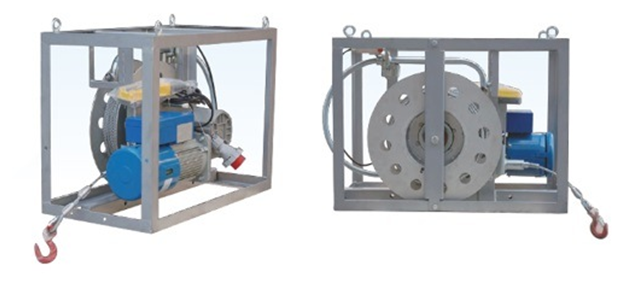

Lifting equipment Material

Compact and reasonable design, collecting wire rope device is driven directly by hoist.

Limit switch for vertical lifting & horizontal moving, end of wire rope sensor and no power descent in case of power failure.

Wireless controller and mechanic overload sensor (option)

Lighter design & more economic solution

– The wire rope roller is driven by the hoist

– Overload limit device (option)

– Wireless controller and mechanic overload sensor (option)

Glass Lifter Sucker 400-600kg

Suspended platform can be used for installing the curtain wallglass,and the glass lifting sucker canbeused for lifting.

Component function description

Vacuum pump: oil-free air-cooled vacuum pump, DC12V, DC charging type to generate vacuum, itis the core part of the vacuum system, the highest vacuum is 75%.

Vacuum suctioncup: used to adsorb on the surface of the workpiece, and the rubberis in contact with the workpiece to ensurethatitwill not damage the surface of the workpiece.

Vacuum filter: used to filter impurities and particles on the surface of the workpiece or in the air to ensure the service life of the vacuum pump.

Pressure sensor: used to visually display the vacuum pressure of the system to the operator and providesafety assurance; when the pressure of the vacuum system is insufficient, it transmits electrical signals to the alarm system.

Push-pull valve: control and switch the passage between the vacuum pump and the suctioncup, the suctioncup and the atmosphere.

Vacuum check valve: When the system ispowered off, itwillautomatically close the passage between the vacuum pump and the atmosphere, lock the vacuum energy of the accumulator, and provide sufficient pressure holding time to ensurethat the work piece will not suddenly fall.

Manualball valve: used to manually open or close the passage between the vacuum pump and the suctioncup, easy to maintain.

Alarm indicator: when the suction of a single group of suctioncupsisinsufficient, the corresponding indicator will alarm.